-

Studer S33 CNC Grinder

CNC cylindrical grinding machine for external, surface and internal grinding.

Turret wheelhead for external, surface and internal grinding (option)

External grinding wheelhead with grinding wheel on the right, swiveling to 0° or 30°.

Frequency-controlled motor grinding spindles for external or internal grinding.

External and internal grinding in one clamping possible.

C-axis for universal workhead, for thread and form grinding.

Longitudinal slide with rotary table, swiveling up to 8.5°.

StuderGRIND programming software for creating grinding and dressing programs on an external PC

Short setup and change-over times with STUDER Quick-Set

-

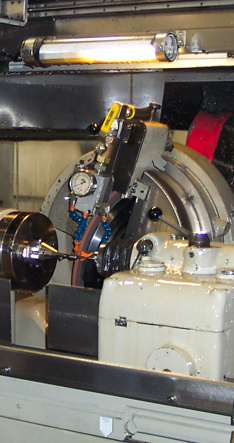

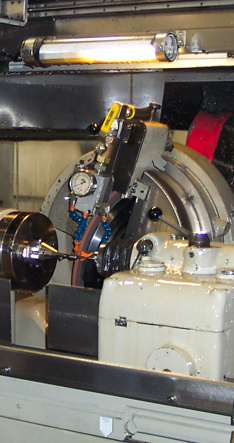

Automated Mitsubishi RD 23 CNC Angle Head O.D. Grinder

For higher production jobs and “lights out” capable.

Equipped with a probe for shoulder location, and Control

Gage in-process gauging system for Diameter size. Westech

Ganty loading system with reversing station for “Complete

Part Grinding” in one loading of the system. Max part size

for Auto loading: 5.9” dia. by 10” long work piece.

-

(3) Mitsubishis RD 23-B35A Angle Head Cylindrical OD

Grinder

Equipped with location probe. Maximum swing = 9.1"

dia., maximum grind =

5.9" dia., maximum distance between centers 13.8". Fanuc

series 16GC CNC controller.

-

Studer model S20 CNC

Universal cylindrical grinding machine for internal and

external grinding plus studerform software for vector

generating out-of-round forms. Maximum swing, 7.8 inch

diameter, 15.75 inches between center, fanuc series 16GC

control with 32 bit processors.

-

Drake 6-36 CNC Thread Grinder with Fanuc fully integrated Automation system.

Complete with integrated automatic loading system utilizing a gantry

system and a robot for loading. Also included is a probe for

re-aligning existing threads and finiding shoulders. New

coolant system to be utilized by both thread gridners

includes chiller system and a Oberlin pressurized filtration

system to improve surface finish and minimize waste oil.

-

Drake 12-45 CNC Thread Grinder

Precision Grinding of Standard 60 deg threads, multiple

start threads and worms, 14 deg ACME threads, 20 deg worms

and CNC dressed special forms. Capacity to Grind a 12” dia.

by 45” long work piece.

-

Kent Surface Grinder: Model KGS-250AHD

Features a 8” X 18” Walker fine division magnetic chuck.

Precision 3Axis hydraulics with Auto incremental downfeed.

Maximum Part Size: 8” Wide X 18” long X 8” high. Max work

piece weight: 550 lbs.